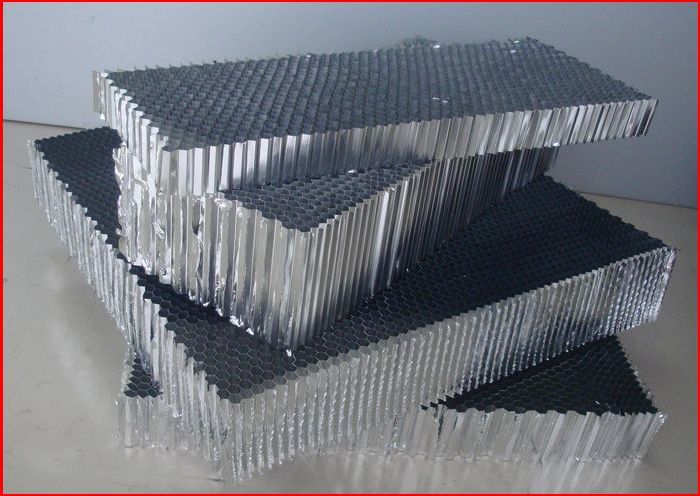

High grade expanded Aluminium honeycomb in a variety of sizes to suit any application.

All Aluminium honeycomb core can be supplied in unexpanded form.

50mm thick 8mm core cell to suit lazer or water cutting tables.

Aluminium Checkerplate Honeycomb. (special order only)!

High grade Aluminium honeycomb core panel.

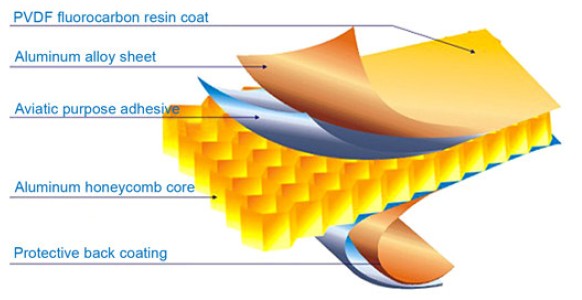

Honeycomb Materials were born for Aviatic applications in the beginning, and they have been widely acknowledged for their unique stiffness-to-weight-ratio. Our manufacturing facility has succeeded in bringing it into commercial application. It consists of an expanded 3003 alloy hexagonal aluminum honeycomb core in the middle, and a sheet of 3003 H24 aluminum bonded to each side with an Epoxy adhesive agent. This sandwich structure gives this product high strength and a super-flat surface. Aluminum honeycomb core has the advantage of Lightness, so it is very light in weight for transportation and installation.

The traditional thermal pressing equipment, not only has low working efficiency, but most likely will cause the panel to deform or bend due to the sudden change of temperature when panels come out of the press. Our updated Automatic Composite Honeycomb Panel Production Lines produce the honeycomb panel with the following steps:

Feed in → LowTemperature → Middle Temperature → High Temperature → Middle Temperature →Low Temperature → Cooling and Figuration → Product out 』

This continuous and integrated production process is done in a completely sealed environment under high pressure.

It efficiently avoids the problems before they occur.

The honeycomb panel produced by this production process will never deform even if the application environment is damp or subjected to high temperature.

Polycore Aluminium Honeycomb core panels are panels that can be used for a wide variety of applications.

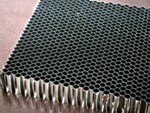

Aluminium Honeycombs possess an excellent strength to weight ratio, and is applicable almost anywhere where lightness and strength are required and its uses are therefore virtually unlimited.

Polycore supplies Aluminium Honeycomb panels tailored to the exact customer requirements.

Polycore Aluminium Honeycomb can be supplied as full Blocks or cut slices, expanded or unexpanded, laminated with fibreglass, bonded to plain or anodised Aluminium sheet.

Applications for Aluminium Honeycomb Core:

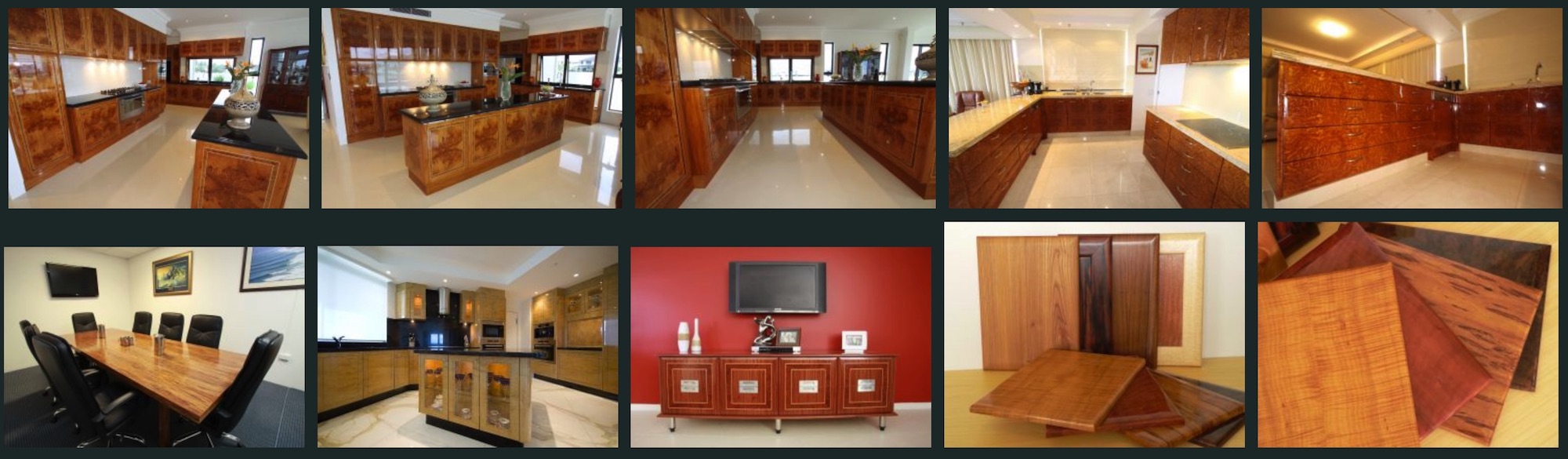

Marine Vessels, Exteriors Architectural, Doors, Walls, Ceilings, Partitions, Cleanroom panels, Heating and air conditioning units, Acoustic attenuation, Electric sheilding enclosures, Air light water directional systems, Curtainwall for high buildling, Exterior cladding, Interior decoration, Marine (bulkhead, partition, ship body, countertop) Rail(Floor, ceiling,interior) Vehicle body, Elevator, interior decoration, Bathroom and kitchen Partition, Industry equipment shell, Public facilities, Signs and advertising industry.

Features:

High thermal conductivity, Flame resistance, Temperatures up to 350F, Excellent moisture and corrosion resistance, Fungi resistance, Light weight, High strength and stiffness, Super flat surface, Thermal insulation, Sound insulation, Vibration Absorption, Easy fabrication and installation, Convenient maintainence, Can be recycled.

Material specifications:

Polycore Aluminium Honeycomb Panels are manufactured from 3003 or 5052 Grade Aluminium.

High grade Aluminium honeycomb core panel.

Honeycomb Materials were born for Aviatic applications in the beginning, and they have been widely acknowledged for their unique stiffness-to-weight-ratio. Our manufacturing facility has succeeded in bringing it into commercial application. It consists of anexpanded 3003 alloy hexagonal aluminum honeycomb core in the middle, and asheet of 3003 H24 aluminum bonded to each side with an Epoxy adhesive agent.This sandwich structure gives this product high strength and a super-flatsurface. Aluminum honeycomb core has the advantage of Lightness, so it is very light in weight for transportation and installation.

The traditional thermal pressing equipment, not only has low working efficiency,but most likely will cause the panel to deform or bend due to the suddenchange of temperature when panels come out of the press. Our updated Automatic Composite Honeycomb Panel Production Lines produce the honeycomb panel with the following steps:

Feed in → LowTemperature → Middle Temperature → High Temperature → Middle Temperature →Low Temperature → Cooling and Figuration → Product out

This continuous and integrated production process is done in a completely sealed environment under high pressure. It efficiently avoids the problems before they occur. The honeycomb panel produced by this production process will never deform even if the application environment is damp or subjected to high temperature.

Polycore Aluminium Honeycomb core panels are panels that can be used for a wide variety of applications.

Aluminium Honeycombs possess an excellent strength to weight ratio, and is applicable almost anywhere where lightness and strength are required and its uses are therefore virtually unlimited.

Polycore supplies Aluminium Honeycomb panels tailored to the exact customer requirements.

Polycore Aluminium Honeycomb can be supplied as full Blocks or cut slices, expanded or unexpanded, laminated with fibreglass, bonded to plain or anodised Aluminium sheet.

Applications for Aluminium Honeycomb Core:

Marine Vessels, Exteriors Architectural, Doors, Walls, Ceilings, Partitions, Cleanroom panels, Heating and air conditioning units, Acoustic attenuation, Electric sheilding enclosures, Air light water directional systems, Curtain wall for high buildling, Exterior cladding, Interior decoration, Marine (bulkhead, partition, ship body,countertop) Rail (Floor, ceiling,interior) Vehicle body, Elevator, interior decoration, Bathroom and kitchen Partition, Industry equipment shell, Public facilities, Signs and advertising industry.

Features:

High thermal conductivity, Flame resistance, Temperatures up to 350F, Excellent moisture and corrosion resistance, Fungi resistance, Light weight, High strength and stiffness, Super flat surface, Thermal insulation, Sound insulation, Vibration Absorption, Easy fabrication and installation, Convenient maintainence, Can be recycled.

Material specifications:

Polycore Aluminium Honeycomb Panels are manufactured from 3003 or 5052 Grade Aluminium